Fast, simple and effective. These are the 3 basic principles that govern our work at Kimua when we design and manufacture our handling, hoisting and transport solutions for bulky, delicate or heavy loads. Our work processes comply with the highest quality standards in every phase of the project, and rely on a highly qualified team that brings passion, knowledge and experience to each of our solutions.

At Kimua, being able to offer the highest quality with simple and effective tools, in an agile and customised way, making use of the most innovative technology, is part of our DNA as an engineering company since our inception. These values are more than just a work philosophy: they have made us a benchmark in the hoisting and lashing of heavy machinery in sectors such as onshore and offshore wind energy, combined cycle and gas, construction, railway, aeronautical and nuclear.

All of this, together with the flexibility we offer with our customised solutions for each need and project, means that we can boast a high rate of satisfaction and recurrence among our collaborator portfolio.

These are just some of the reasons that make our clients choose us as a strategic partner to tackle the needs of their projects and objectives. But we want to show you in more detail all these arguments and values, so we have created this post reviewing our strengths as a company. Plus, we give you 5 reasons why you will trust Kimua as your ally when it comes to designing and manufacturing comprehensive solutions for load handling.

Contact us for all those projects that require quality tools and custom solutions for load transport and hoisting.

1. Flexibility and customisation

One of our main value propositions is the flexibility that we offer when designing and manufacturing load handling solutions. Our turnkey projects are adapted to the specific needs of each client, devising and building the specific tools required by each situation and sector, always meeting agreed deadlines. In this sense, the trust we generate by responding within the set deadlines is valued as an important competitive advantage in our proposals, which is undoubtedly the reason behind our very high client repeat purchase and satisfaction rates.

In addition to our customised solutions, we also offer a renting service, which is another example of our ability to adapt to the needs and resources of each client. The goal of this type of solution is to be able to take advantage of load handling solutions that have already been tested and developed over a certain period of time and provide additional agility. We use advanced remanufacturing processes to ensure that all rented solutions meet the same quality and reliability features as an ad hoc solution.

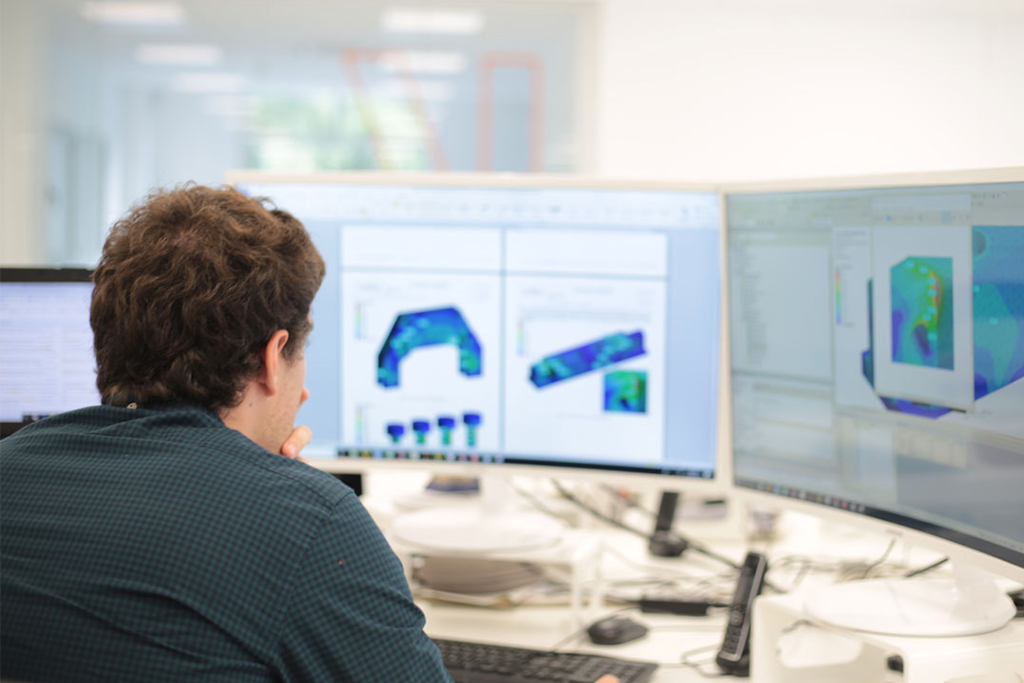

2. Constant commitment to RDI

As an expert engineering company in load handling, technology and innovation are present in our daily work. Our team has expert engineers in welding, machining, hydraulics and electronics, and is constantly learning and training to drive the optimisation of our products and range of solutions. The goal? To be able to face any and all challenges with advanced knowledge and cutting-edge technology.

Examples of this are our Arin line of ultra-lightweight boxes for transporting and hoisting goods even in the most hostile and challenging conditions, like the offshore wind industry, or the use of reverse engineering to transfer a physical model into a virtual one, making an exact copy of a tool, or to verify the dimensioning of a part before and after a load test.

3. Safety of loads and operators

Guaranteeing safety in load transport, handling and hoisting is fundamental for Kimua. Due to the nature of the goods and equipment we work with -heavy, bulky, delicate or expensive- safety is an essential requirement to avoid any kind of risk both for the load itself and for the operator handling it.

For this reason, brackets and devices designed and manufactured by Kimua comply with all certificates and quality standards in order to ensure that loads are handled with absolute safety and efficiency. In order to guarantee this, we are constantly subject to internal and external audits that verify adequacy to client specifications and compliance with international regulations. In this sense, we are accredited by international institutions such as DNV-GL and TUV, and we have certifications both at the management (ISO 9001, ISO 14001, ISO 45001) and manufacturing level (EN1090, ISO 3834-2).

Likewise, the most demanding safety criteria are applied to personnel in charge of handling the loads. In addition, we provide our clients with different training activities aimed at providing all the necessary information and support related to the safety of the people who handle the different solutions.

4. Traceability and transparency

We are aware of the importance of information during all the phases of the project, both at the level of tracking and traceability, as well as communication and subsequent training.

Within our wide range of solutions, we cover all the phases that make up a project, from initial consulting to Site Acceptance Test (SAT), offering complete traceability from the origin of the proposal. Throughout its development, we promote total transparency and constant communication with technicians, and we offer a customised training service adapted to each client, using virtual reality for cases where a traditional demonstration is not possible.

5. Testing in real environments

Being able to guarantee that the products manufactured are completely suitable for industrial use and that they comply with all safety certificates are just some of the advantages of our Lamia static test bench.

Lamia is our own 1,000 tonne test bench. It is a fully modular, portable and monitored test bench where you can test the real quality of the manufactured product and check that the solution meets all specifications. Likewise, it can identify aspects that may generate any type of problem with high precision levels, since it carries out a detailed analysis of the components, materials, vibrations and durability of the tested element in order to correct it if necessary.

In the case of dynamic tests, we use the Moog platform.

If you need further information about solutions or applications for your specific project, contact us and tell us about it. We will know how to attend to your needs and challenges.